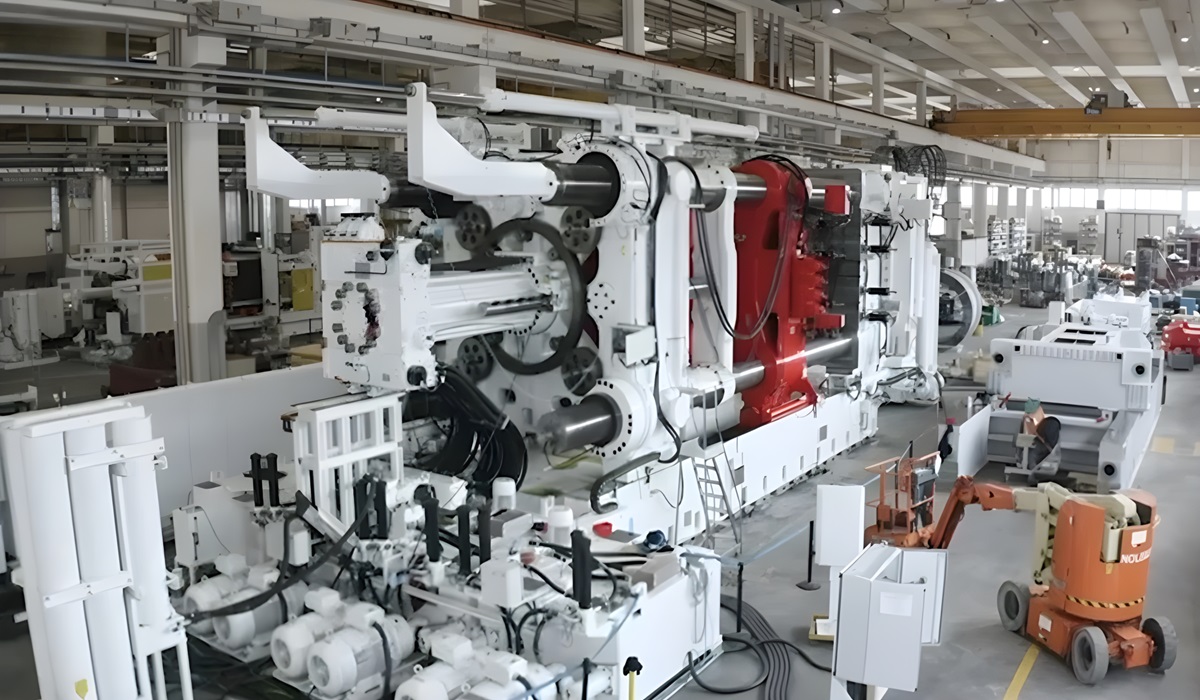

Tesla’s Giga Press, Forever Changed The Way Automobiles Are Built

- Kingston Bailey

- Business

- D.O.C Supplements - Trending News

- Technology

- July 23, 2024

Image Credit, IDRA

Tesla’s Giga Press has revolutionized automotive manufacturing with its ability to produce large, single aluminum castings for vehicle frames. This colossal die-casting machine significantly changes the traditional manufacturing process by replacing the need for numerous smaller parts and complex assembly techniques with a streamlined, efficient approach.

In the past, automotive manufacturing involved creating numerous individual components that were then welded, soldered, and assembled. This method was not only labor-intensive but also led to considerable material waste and higher production costs. The introduction of the Giga Press allows for the casting of entire sections of a vehicle’s frame in a single operation. This advancement reduces the complexity of the assembly process, leading to faster production times and lower costs.

The impact of the Giga Press extends beyond efficiency. By producing large, single-piece castings, the machine improves the structural integrity of the vehicles. Fewer joints and connections mean fewer potential weak points, resulting in stronger and safer vehicles. This improvement in quality and durability is a significant advantage over traditional methods.

Environmentally, the Giga Press contributes to more sustainable manufacturing practices. It reduces material waste and energy consumption, aligning with broader goals of environmental responsibility. By minimizing the resources required for production, Tesla’s approach sets a precedent for eco-friendly manufacturing practices.

As the Giga Press technology becomes more widespread, it is likely to influence industry standards. Other manufacturers are expected to adopt similar techniques, leading to broader changes in automotive production. This shift represents a significant move towards more efficient and sustainable manufacturing processes.

The Giga Press is not just a technological innovation; it is reshaping the future of automotive production and setting new industry standards.