Roll Forming Machine Market Witnesses High Growth Due To Increasing Demand From Automotive and Construction Industries

- Ronak Shah

- World News

- January 8, 2025

The roll forming machine market is estimated to be valued at US$ 9.34 Bn in 2024 and is expected to exhibit a CAGR of 3.6% over the forecast period 2024- 2031, as highlighted in a new report published by Coherent Market Insights.

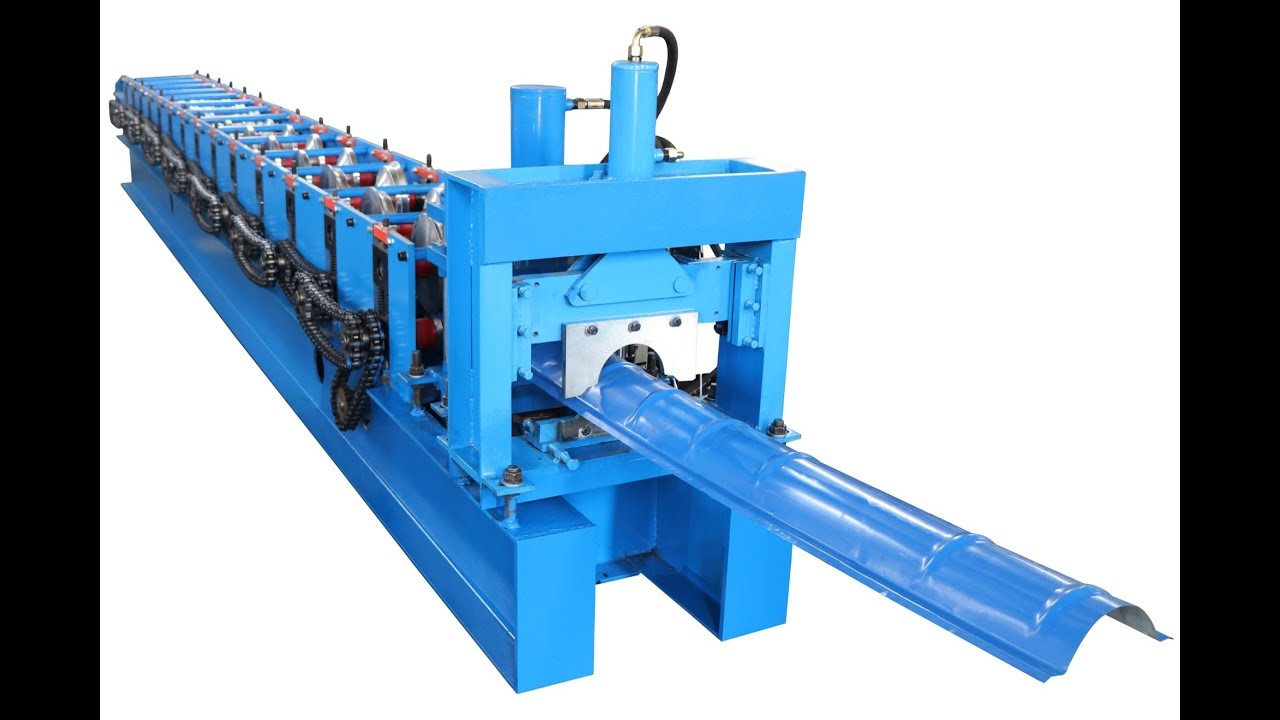

The growth of the roll forming machine market is driven by the increasing demand from the automotive and construction industries. Roll forming machines are extensively used in the automotive industry for manufacturing vehicle body parts such as doors, panels, and chassis profiles. They help automotive OEMs in mass production of parts with precision and consistency. Similarly, in the construction industry, roll forming is used to produce metal roofing, siding, window frames, and floor joists. This reduces the requirement of manual labor and improves productivity. Furthermore, ongoing infrastructure development projects across both developed and emerging countries are fueling the demand for construction materials, which is supporting the growth of the roll forming machines market.

Key Market Trends:

Adoption of Industry 4.0 technologies: Major roll forming machine manufacturers are focusing on integrating Industry 4.0 technologies such as IoT, AI, advanced robotics, and virtual reality into their machines. This allows remote monitoring of the machines, predictive maintenance, and improves manufacturing processes.

Growing popularity of servo-driven roll forming machines: Servo drive technology uses sensor feedback for precise control over motor movement. This increases flexibility, reduces setup time, and improves uptime of roll forming machines. Owing to these benefits, the demand for servo-driven roll formers is growing compared to conventional hydraulic machines. More coverage can be found in the sample copy.

Cold Forming Segment Opportunity

Cold forming of sheet metal is one of the major market opportunities for roll forming machines. Cold forming does not require pre-heating of the metal sheets and is thus more energy efficient than hot forming. Around 60% of the global sheet metal processing is done through cold forming. Roll forming is widely used in cold forming applications to manufacture products such as panels, panels, gutters, roofing and siding materials. The cold forming segment is expected to grow at a CAGR of 4.2% during the forecast period driven by the growth in the construction and industrial manufacturing industries.

Hot forming allows processing of stronger and harder sheet metal alloys such as steel. Around 40% of sheet metal processing involves hot forming. Hot formed parts find applications in applications requiring high strength such as in the automotive, hardware and appliance industries. Roll forming plays a key role in hot forming to shape metal sheets that have been pre-heated to high temperatures. The hot forming roll forming machine market is projected to rise at a CAGR of 3% till 2031 due to the rising automobile production and demand for durable manufactured goods.

Key Market Takeaways

The global roll forming machine market is anticipated to witness a CAGR of 3.6% during the forecast period 2024-2031, owing to rapid industrialization and growth in the construction and automotive sectors.

On the basis of type, the C-frame roll forming machines segment is expected to hold a dominant position, accounting for over 35% of the global market share due to the low cost and suitability for high-volume low-variety production needs of most industries.

By material, the steel roll forming machines segment is estimated to dominate with a market share of 45%, due to the wide use of steel in construction, industrial manufacturing and automotive production.

Regionally, North America is expected to hold a dominant position over the forecast period with a market share of 30%, due to high automation in manufacturing sectors and presence of major roll forming machine manufacturers in the region.

Competitor Insights:

JMT USA

AMADA

Jouanel Industrie

Metform international

DMS Machines

Baileigh Industrial

Haeusler Ag

HAZEMAG UK

Bidwell Tool

California Custom

Recent Developments in Roll Forming Machine Market

In July 2023, AccuRoll launched its new NX series of servo-driven roll forming machines. The NX line features fully integrated servo motors,drives and controls for high-speed, synchronized roll forming. Also in July, Kingsland Engineering expanded its KS range of high-speed roll formers with 350 FPM line speeds. The growing demand for servo technology and high production speeds in roll formers is expected to continue in 2024 as well.

The roll forming machine industry is poised for further technological advancement and evolving demand drivers in 2023-2024. Automation, multi-function integration, servo-driven speed and digitization will remain prominent developmental areas. Meanwhile, application scope expansion and penetration into new global markets are expected to fuel overall market growth. Roll forming OEMs will seek to optimize production efficiency, lower per-part costs and enhance manufacturing connectivity through their product innovations over the coming years. Full coverage of the report available here.