Metal Additive Manufacturing Market Is Estimated To Witness High Growth Owing To Growing Demand From Automotive and Aerospace Industries

- Ronak Shah

- U.S.A

- January 29, 2025

The Metal Additive Manufacturing Market is estimated to be worth US$ five.Eighty five Mn in 2024 and is predicted to showcase a CAGR of 13.7% over the forecast length 2024- 2031, as highlighted in a brand new file published by means of Coherent Market Insights’ The developing call for from car and aerospace industries is one of the most important drivers contributing to the growth of the steel additive production marketplace.

Metal additive manufacturing helps in reducing weight and improving fuel efficiency of aircrafts and automobiles. It also enables complex designs that were not possible through conventional methods. In addition, reduced lead time and production costs associated with metal additive manufacturing is another factor fueling the market growth. However, high capital investment and lack of standardization process are some of the factors that may hamper the market growth.

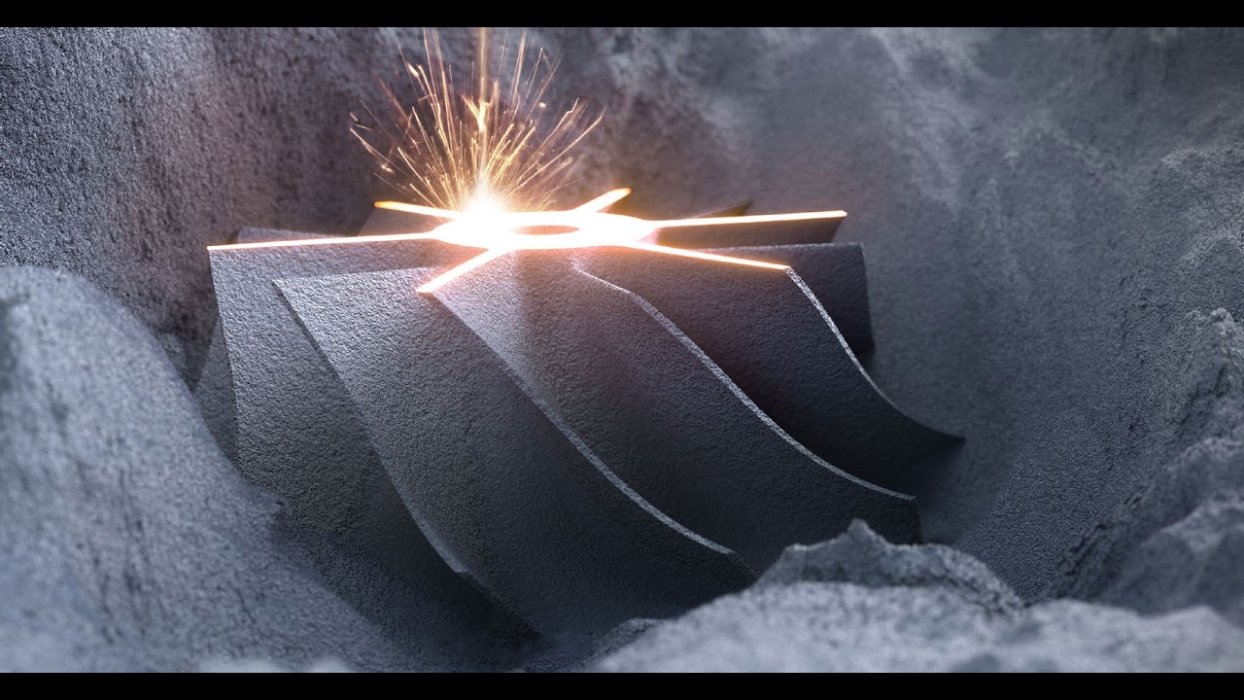

Key Market Trends: Powder bed fusion technology dominated the metal additive manufacturing market in 2021. Powder bed fusion technique uses a thermal energy source such as laser or electron beam to fuse metallic powder together. Key advantages of this technology include ability to produce fully dense metal parts with superior mechanical properties as well as complex geometries. Rising demand for functional metal parts across automotive and aerospace industries has increased adoption of powder bed fusion technology.

Titanium and nickel-based alloys find wide application in metal additive manufacturing due to their high strength, corrosion resistance and biocompatibility. Titanium alloys are increasingly used to produce dental implants, orthopedic implants and aerospace components. Nickel-based alloys such as INCONEL are popular choices for high-temperature applications in industries such as aerospace, marine and chemical. Their usage has increased significantly over the past few years owing to advantages like reduced total ownership costs and design complexity enabled by 3D printing.

Metal Additive Manufacturing Market Opportunities: Metal 3D Printing By Technology: Metal 3D printing is expected to capture around 35% share of the overall additive manufacturing market by 2024. Key technology types include powder bed fusion, direct metal laser sintering (DMLS), and electron beam melting (EBM). These technologies offer benefits like reduced waste, intricate design capabilities, and reduced lead times. Powder bed fusion technology is gaining significant traction in the metal 3D printing industry. It held over 50% share in 2019 owing to benefits like ability to print high-density metals and alloys.

Metal 3D Printing By Application: Aerospace and defense is a major application area for metal additive manufacturing, accounting for over 30% share in 2019. Metal 3D printing helps aerospace OEMs and part manufacturers reduce weight, improve performance, and lower costs of aircraft components. It is progressively being used to print critical components like engine parts with intricate internal passages. Applications in other industries like automotive, dental and medical are also growing at a double digit CAGR. Complex interiors, personalized medical implants and high strength car parts can now be manufactured using this technology.

Key Market Takeaways: The global metal additive manufacturing market size was valued at USD 5.85 billion in 2024 and is expected to grow at a CAGR of 13.7% during the forecast period from 2024-2031. Powder bed fusion technology segment accounts for the major share due to ability to print a variety of metal alloys at high precision.

On the basis of application, the aerospace segment holds a major share of over 30% owing to growing acceptance of 3D printed components in aircraft structure. Automotive and medical segments are also growing rapidly due to benefits of lightweighting and customized products.

North America dominated the market with over 35% share in 2024 led by presence of major players and high adoption in aerospace industry. Europe and Asia Pacific are also significant markets driven by government initiatives for additive manufacturing.

Competitor Insights: The key players operating in the market include 3D Systems, TRUMPF, Renishaw and SLM Solutions. Collaboration between manufacturers and end users for application development has been a major trend. The technology providers have also adopted strategies like acquisitions for capabilities expansion.

Recent Developments: In August 2023, Ford partnered with VELO3D to qualify its Sapphire metal additive manufacturing system for production-intent automotive components. Meanwhile, Lamborghini debuted a 3D printed titanium exhaust for the Sián hybrid supercar showcasing the potential for high-performance auto parts. Other automakers are utilizing metal additive manufacturing to expedite development cycles through rapid prototyping. As regulations around self-driving vehicles evolve, 3D printed sensors and associated parts are seeing increasing interest. The flexibility, reduced lead times and ability to produce low-volume specialized components makes metal additive manufacturing an attractive option for automotive applications. More information in full report.